Themes

We have identified four major themes in hexagonal materials in order to address processing, properties and performance in the proposed synergistic manner bringing to bear the range of experimental, characterization and modelling techniques. All of the themes are interdependent and cannot be successful on their own. For example, the research in micromechanics and sonics on texture and macro-zone detection depends upon x-ray, SEM and EBSD characterization and property determination from fundamental mechanisms; conversely, understanding high-rate twin nucleation in the fundamental mechanisms work and slip localization in the nuclear performance work depends upon knowledge of microstructural-level stress and slip levels to be obtained from the micromechanics work. Similar arguments and examples can be provided for all the themes.

HexMat Themes

Theme I. Fundamental Mechanisms

Fundamental Mechanisms

Principal Investigator: Prof Angus Wilkinson, University of Oxford

Research Programme:

FT1: Experimental Technique Developments

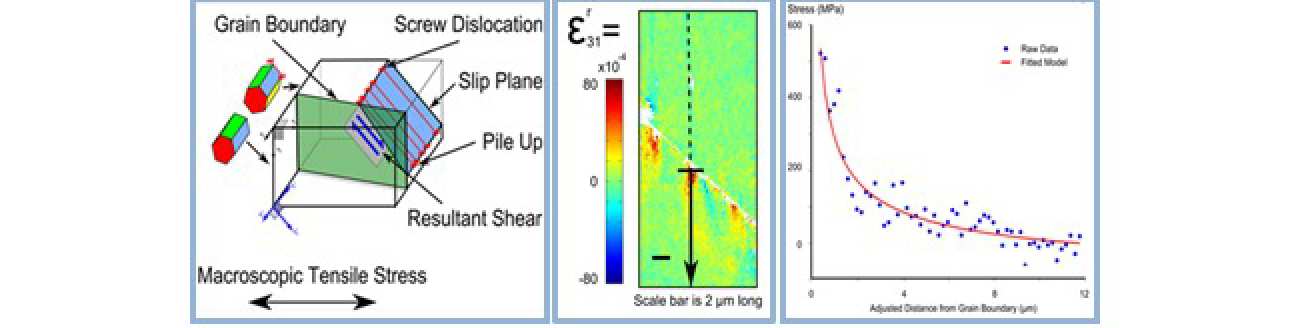

FT2: Slip Transfer at Grain Boundaries

FT3: Deformation Twinning

FT4: Slip Planarity and Slip Band Spacing

FT5: Shear Band Formation

FT6: Elastic Anisotropy of beta Phase

Theme II. Micromechanics and Sonics

Theme II. Micromechanics and Sonics

MT1: Polycrystal Ultrasound Dynamics

MT2: Ultrasonic Texture Detection

MT3: Intra- and Trans-crystal Behaviour

MT4: Polycrystal Property Prediction

MT5: Adiabatic Shear in High-rate hcp Deformation

Theme III. Aerospace Performance

Theme III. Aerospace Performance

AT1: High Cycle Fatigue

AT1: High Cycle Fatigue

AT2: How Short Cracks Turn into Long Cracks

AT3: Dwell Fatigue

AT4: The role of temperature and rate

AT5: The role of oxygen

AT6: Quantifying microstructures

AT7: High rate surface damage and fatigue

AT8: Twinning and high rate deformation

AT9: Developing improved microstructures and alloys

Theme IV. Nuclear Performance

Theme IV. Nuclear Performance

NT1: Developing experimental protocols for proton irradiation of Zr alloys in order to simulate neutron irradiation

NT2: Developing methods for mechanical experiments of proton irradiated material in context of fatigue and DHC

NT3: Microstructural factors that affect flow localisation and slip transfer

NT4: Effect of hydride formation on deformation mechanisms in irradiated Zr

NT5: Comparison of crack formation from defects in irradiated and non-irradiated material

NT6: Effect of aqueous corrosion environment on crack formation