Welcome to SETTL - Imperial College London's Sustainable Energy Technology and Turbomachinery Lab. Our world class expertise in turbocharging and exhaust gas energy recovery, supported by unique test facilities, can help your turbochargers run as efficiently as possible.

Overview

The Turbo Group at Imperial College is a world-leading centre for experimental and numerical aerothermal research into turbochargers, whole engine air systems, and waste heat recovery. Our expertise covers:

- Experimental measurement of steady and pulsating flows in turbocharger turbines, using our high-speed eddy current dynamometer; and in turbocharger compressors, using our motored compressor test rig

- Experimental measurement of transient-pulsating flows in high performance engine air systems, using TASR, the Transient Air System Rig

- Research and testing of electrical turbochargers, superchargers and turbogenerators, and the associated cooling and heat transfer in electrical machines

- Steady and unsteady turbomachinery 3D CFD

- Multi-objective design optimization of turbocharger turbine wheels and volutes, informed by 3D CFD

- 0D and 1D turbocharger performance and gas dynamic models for engine-turbocharger simulations

- Modelling of hybrid and electric vehicles

- Design, development and testing of novel turbocharging concepts

We provide consulting services into all these areas through IC Consultants Ltd (ICON), the consulting company of Imperial College London.

Latest news

Launch of the MHIET-Imperial Future of Boosting Innovation Centre, February 2019

The MHIET-Imperial Future of Boosting Innovation Centre was officially launched on 1 February 2019. This long-term partnership in turbocharger development will bring together expertise across advanced research on boosting and electrification technologies as well as in critical areas for the understanding of the complex physics behind these processes. The aim of this collaboration is to carry out detailed research on state-of-the-art turbocharger and exhaust energy technologies to further improve engine performance and operation.

Prime Minister of Malaysia, Tun Dr Mahathir Mohamad, visits the Turbo Group laboratory, 24 September 2018

Photograph: Professor Ricardo Martinez-Botas (left) and Dr Srithar Rajoo (right) explain the research of the Turbo Group to the Prime Minister of Malaysia, Tun Dr Mahathir Mohamad (centre).

The Prime Minister of Malaysia, Tun Dr Mahathir Mohamad, visited the Turbo Group laboratory today, during his visit to Imperial College London as part of his tour of the United Kingdom. Professor Ricardo Martinez-Botas, supported by research students and staff, gave the Prime Minister a detailed review of the low carbon vehicle research being carried out in both the Turbo Group and the wider Department of Mechanical Engineering, including our unique experimental facilities, as well as advanced technologies such as electrically-assisted turbocharging and batteries for hybrid and electric vehicles. The Turbo Group has long standing links with Malaysia, now formalized through the UTM Centre for Low Carbon Transport (LOCARTIC), a collaborative research venture between Universiti Teknologi Malaysia and Imperial College London.

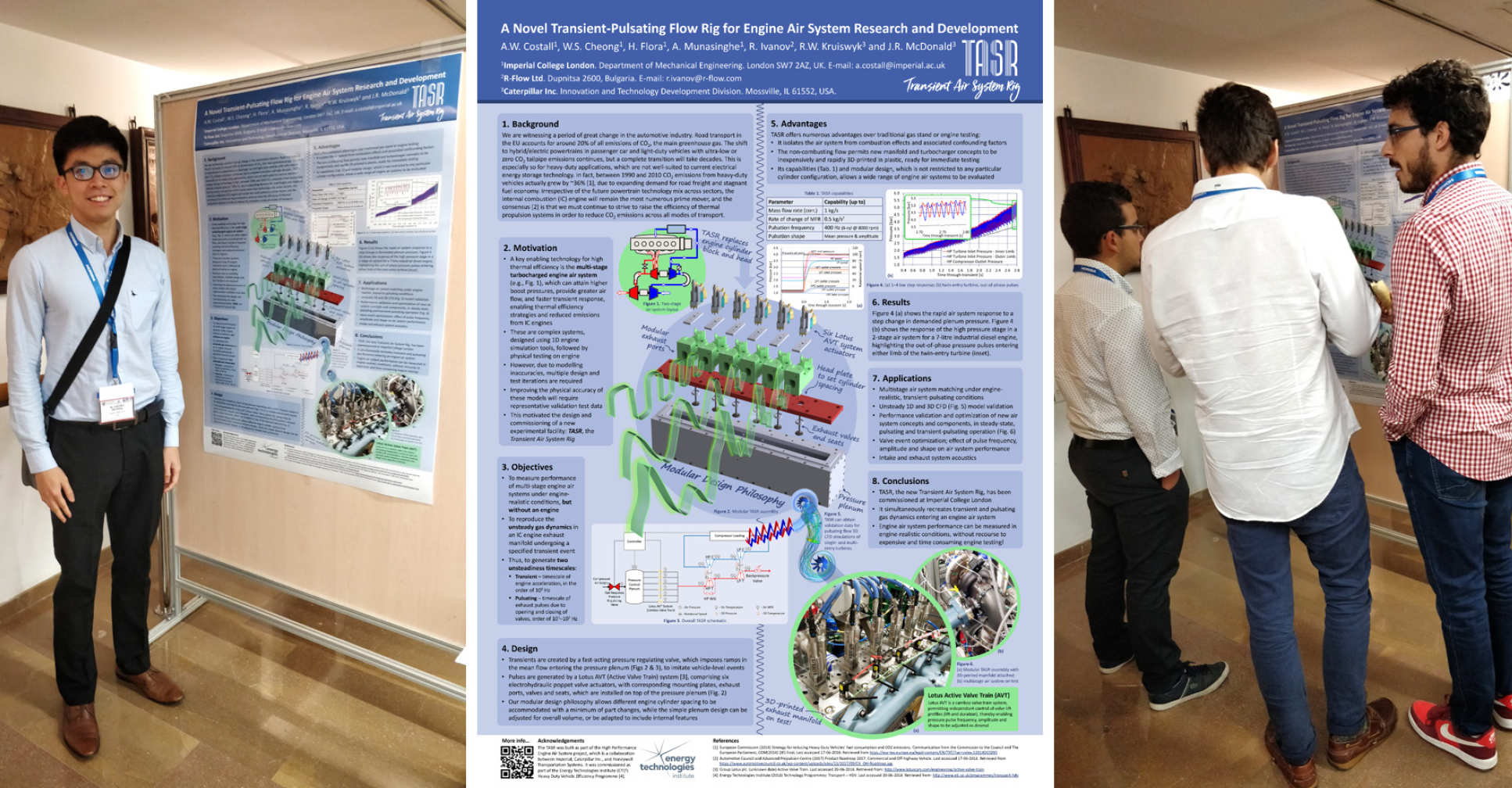

Vincent Cheong and Aaron Costall present TASR poster at THIESEL Conference, September 2018

Photographs: Vincent Wei Sheng Cheong; the poster; conference attendees learn about TASR during the poster session.

Photographs: Vincent Wei Sheng Cheong; the poster; conference attendees learn about TASR during the poster session.

Vincent Cheong and Aaron Costall presented their poster, "A novel transient-pulsating flow rig for engine air system research and development", which describes the new TASR facility, at the THIESEL 2018 Conference on Thermo-and Fluid Dynamic Processes in Direct Injection Engines, September 2018.

Experts build pulsed air rig to test 3D printed parts for low carbon engines, June 2018

--tojpeg_1537809146812_x2.jpg) Photographs: TASR employs a Lotus Active Valve Train (AVTTM) system to generate engine-realistic exhaust pulses, while cold flow allows new manifold designs to be 3D-printed and tested in plastic; a two-stage air system for an off-road heavy-duty diesel engine on test.

Photographs: TASR employs a Lotus Active Valve Train (AVTTM) system to generate engine-realistic exhaust pulses, while cold flow allows new manifold designs to be 3D-printed and tested in plastic; a two-stage air system for an off-road heavy-duty diesel engine on test.

The new Transient Air System Rig (TASR) was publicized in an Imperial College London website article: "Experts build pulsed air rig to test 3D printed parts for low carbon engines", in June 2018. For further information, please visit the TASR page.