Other fully funded PhD projects

In the Department of Materials, we have a range of exciting PhD opportunities available in our different research groups.

We have listed our available opportunities below.

Accordion

Rational Design of Sodium Ion Batteries

Supervisors: Prof Mary Ryan and Prof Milo Shaffer (as part of a research team involving Prof Magda Titrici, Dr Ajit Panesar and Dr Ifan Stephens

Start date: As soon as possible

Duration: 3.5 years

Entry requirements: Applicants should have a keen engagement and solid background in materials processing and characterisation and a demonstrated interest in electrochemical energy storage. Experience of air-sensitive chemistry, electrochemical characterisation and advanced characterisation will be an advantage. Applications are invited from candidates with (or who expect to gain) a first-class honours degree or an equivalent degree in Chemistry, Materials, Engineering or a related discipline.

Funding: Funding is available for UK citizens and EU citizens who have resided in the UK for the past three years. The studentship is for 3.5 years starting as soon as possible and will provide full coverage of tuition fees and an annual tax-free stipend of approximately £17,609.

Closing date for applications: Open until filled

PhD Industrial Studentship in “In situ Evaluation and Nanoscale Design of Battery Electrodes for Optimized Performance and Lifetime”

Project summary: Applications are invited for a Ph.D. studentship focused on nanoscale battery anode design within the Chemistry and Materials Departments at Imperial College London. Whilst the project will have a fundamental focus, it will contribute to the wider development of energy storage systems. As part of a collaboration with a major international industrial partner, the research will target the development of sodium ion battery systems for grid storage to support the implementation of renewable energies.

The project will focus on fabrication and detailed assessment of optimized architectures for electrodes in sodium ion batteries, based on numerical simulations carried out as part of the wider project. In particular, the PhD program will develop and implement advanced operando characterization tools, based on X-ray, Raman and electron microscopy. It will exploit state-of-the-art equipment available at Imperial, including a brand new suite of atomic resolution instruments specified for electrochemical device studies, and in situ cells available as part of a collaboration with the Diamond Light Source national Facility.

Queries: Informal enquiries and requests for additional information for this post: Professor Mary Ryan or Prof Milo Shaffer.

Any queries regarding the application process should be directed to John Murrell.

Committed to equality and valuing diversity. We are also an Athena Bronze SWAN Award winner, a Stonewall Diversity Champion and a Two Ticks Employer.

Development of high performance low operating temperature protonic conducting ceramic electrolysers

iCase Studentship in “Development of high performance low operating temperature protonic conducting ceramic electrolysers”

Academic Supervisor: Prof. Stephen J. Skinner (Imperial)

Industry Supervisor: Dr Man Yi Ho (SLB)

Start Date: October 2024

Duration: 4 Years

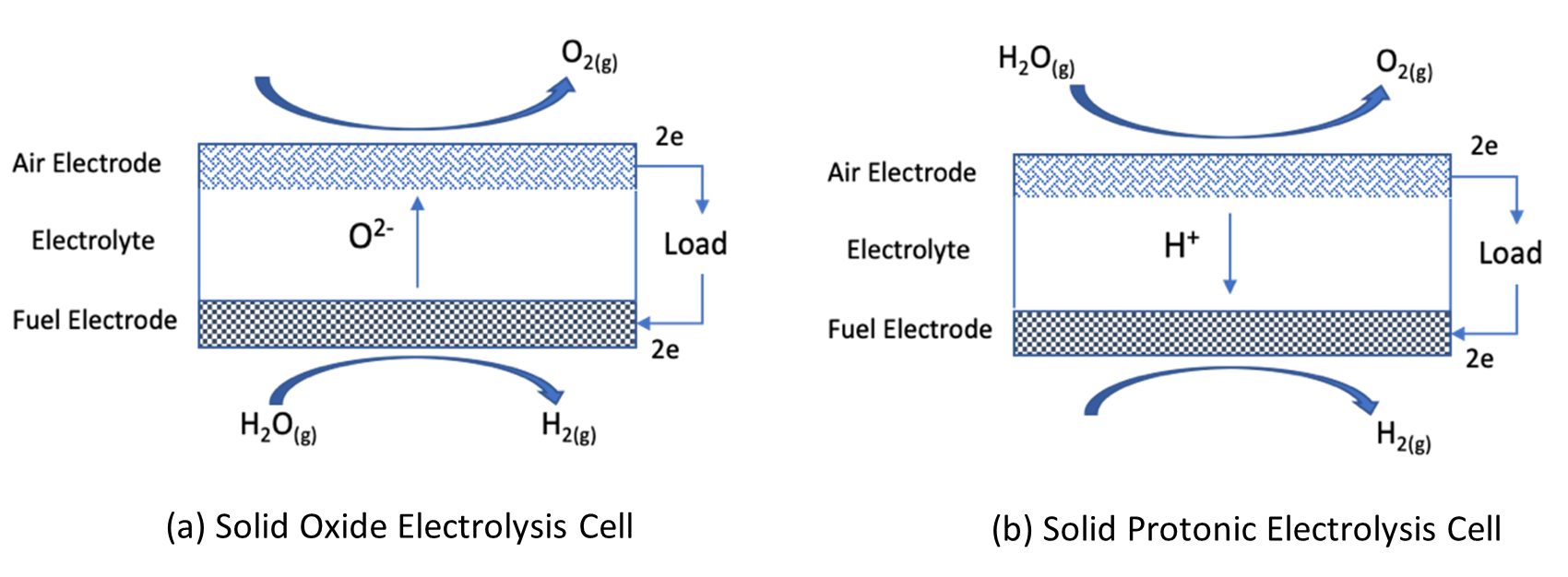

Solid oxide proton conducting ceramics, discovered by Iwahara1 over 30 years ago have been extensively investigated for their application in proton conducting fuel cells. The recent and growing interest in the production of green hydrogen, underpinned by international governmental strategies, including the US hydrogen hubs,2 has renewed interest in proton conducting oxides for application in high temperature electrolysers. Proton conducting ceramic electrolysers (PCEC) offer several advantages over the comparable solid oxide electrolyser (SOE), Figure 1, with temperatures compatible with waste heat from industrial processes, thus offering a route to decarbonisation of industrial processes. Whilst the PCEC has been identified as a route to green hydrogen production there are numerous areas for materials and systems optimisation, with mechanistic understanding of the electrode processes at both anode and cathode being of key concern.

Figure 1: Comparison of a) solid oxide and b) solid protonic electrolysis cells

In this PhD project we will focus on developing detailed mechanistic understanding of the operation of composite electrodes consisting of a novel hexagonal perovskite proton conductor with an electronic conducting phase (e.g. Ni) incorporated. These transport processes include ion transport through the oxide, charge transfer across interfaces and both hydrogen and oxygen evolution reactions. Recent developments of the Ba7Nb4MoO203,4 and Ba3NbMoO8.55 compositions have suggested attractive levels of both protonic and oxide ionic transport, but as yet there have been no studies of the electrochemical performance of these materials in devices, nor any understanding of the durability and cyclability of the cells, including materials thermal expansion behaviour. To further develop knowledge of this technology there will be two key aspects to this research project: 1) manufacture and testing of single cells based on the identified hexagonal perovskite compositions, including detailed characterisation of the mechanism of ion transport and subsequent degradation of electrochemical performance, including selection of compatible electrodes and 2) development of new compositions based on the prototypical materials, and engaging with materials discovery approaches such as molecular dynamics and density functional theory calculations to provide predictors for performance. From these studies we will identify the rate limiting electrochemical processes in next generation materials in a planar electrolysis cell.

[1] H. Iwahara, Solid State Ionics, 28-30 1988 573-578

[3] M. Yashima et al, Nature Commun., 12 2021 556

[4] S. Fop et al, Nature Mater., 19 2020 752-757

[5] S. Fop et al, J. Am. Chem. Soc., 138 2016 16764-16769

Engineering catalytic interfaces for direct alkaline seawater electrolysis

Supervisor(s) – Dr. Reshma R Rao, Prof. Mary Ryan

Start date – 1st October 2024

Duration of funding and funding details – 4 years of funding are available for “UK Residents” as defined by EPSRC, they will provide full coverage of standard tuition fees and an annual tax-free stipend aligned with UKRI (£20,662 for 2023/24).

Closing date – open until the position is filled

Entry requirements: Candidates must meet the college requirements

Project summary: Low temperature water electrolysis is key to enabling green hydrogen production at the terawatt scale. Current water electrolyser technologies require extremely pure water, which limits their design flexibility and imposes resource intensive steps of water purification. Direct seawater electrolysis circumvents these obstacles but is currently limited by the poor activity and stability of catalysts in the presence of ions present in seawater. The slow kinetics of the water oxidation at the anode, the major bottleneck for water electrolysers, is exacerbated in in seawater. Chloride ions, abundantly present in seawater, get preferentially oxidized at the anode and their interaction with the catalyst surface triggers oxy-chloride corrosion mechanisms. This project will aim to design catalysts with an anion-rich surface that can repel chloride ions and thus ensure sustained catalytic performance in the presence of seawater. The student will develop expertise in a combination of electrochemical chacterisation methods, time-of-flight mass spectrometry and operando techniques including optical and surface enhanced infrared absorption spectroscopy to track the evolution of the solid-liquid interface as a function of potential.

Microwave Amplification at the Quantum Limit with Room-Temperature Maser Amplifiers

Supervisors: Professor Neil Alford and Dr Daan Arroo

Start date: October 2024

Duration: 3.5 Years

Entry requirements: Ideally, you will hold, or be expected to achieve, a Master’s degree or a 4-year undergraduate degree at 2:1 level (or above) in a relevant subject, e.g. Material Science, Physics or a related discipline.

Funding: The studentship is for 3.5 years and will provide full coverage of tuition fees and an annual tax-free stipend of £24,237

Eligibility: Applicants must be ‘UK Residents' as defined by the EPSRC.

Project summary:

Masers – the microwave version of lasers - have long been used to detect signals for deep-space communications and radio astronomy due to their exceptional sensitivity and low noise, but traditional maser devices require vacuum and cryogenic cooling which has limited their use to date to these niche applications. The Maser Research Group at Imperial has pioneered the use of quantum materials such as diamond enriched with nitrogen vacancies to create a new generation of masers capable of operating in ambient conditions [Arroo et al., APL], culminating in the development of portable prototype devices which can be tested in realistic environments [Ng et al., APL].

Applications are sought for an ICASE Award studentship to explore how these devices can be optimised through a combination of device and materials engineering. This will include optical and microwave characterisation of functional quantum materials, the design and fabrication of maser devices and testing these devices to achieve quantum-limited measurements.

The project will ideally suit an applicant with an interest in quantum technology and device engineering.

The PhD will be carried out with support from the Henry Royce Institute and will contribute to the work carried out on the NAME Programme grant.

Applications will be assessed as received and all applicants should follow the standard College application procedure. Please apply to the Department of Materials.

Informal enquiries and requests for additional information for these posts can be made to Dr Daan Arroo.

To apply, please go to the application portal.

Queries: Any queries regarding the application process should be directed to Dr Annalisa Neri.

Shielding Materials for Fusion Energy

iCASE studentship in “Development of fusion-grade cemented WC for shielding applications in compact spherical tokamaks”

Supervisors:

Dr Sam Humphry-Baker (Imperial), Dr Florian Bouville (Imperial), and Dr James Wade-Zhu (UKAEA)

Start date: October 2024-October 2025

Duration: 4 years

Entry requirements: A first-class or upper-class second honours degree (or equivalent) in Materials Science and Engineering or a related discipline. A strong background in materials processing and/or characterisation is desired. A demonstrated interest in ceramics and/or materials for fusion will be an advantage.

Funding: 4 years of funding are available for UK Residents (timely applications from exceptional international students will be considered, subject to institutional funding limitations). The funding will cover standard tuition fees, the iCASE UKRI stipend (£21,662 for 2023/24) and project-related costs.

Project summary: The development of advanced radiation shielding materials is critical to enabling safe operation of compact fusion reactors on a commercial basis. Cemented-WC ceramics, which consist of WC particles bonded together with an iron-based binder, are front-running candidate materials due to their excellent thermal, mechanical, and shielding properties. However, the binder may undergo embrittlement, and the WC particles may swell, due to irradiation-induced defect formation. The PhD project will fabricate a new class “fusion grade” cemented-WC composites, which will alleviate these two concerns. This will be achieved by optimising both the composition of the iron-based binder for improved neutron resilience, and the microstructure of the WC grains to accommodate their swelling. Such an approach will yield a material better equipped to withstand the high neutron doses and transmutation effects expected during service. The project will receive support from the UK Atomic Energy Authority in designing, planning, and conducting irradiation damage studies to better understand the irradiation damage response of the fabricated materials.

The UKAEA’s mission is to lead the delivery of sustainable fusion energy and maximise the scientific and economic benefit. This is a response to the national and global need for sustainable and secure low carbon energy supply. The UKAEA will be supporting this project in several ways including:

- Funding towards the project

- Industrial supervision for the PhD student

- Hosting the student for a 3-month secondment on the UKAEA site or at a National Ion-Beam Facility relevant to the project.

Queries: Informal enquiries and requests for additional information for this post: Dr Sam Humphry-Baker.

Understanding interfacial failure in polymer nanocomposites from first-principles

Supervisors: Prof Arash Mostofi (Imperial College London) & Dr Ali Karimi-Varzaneh (Continental Tires Germany Gmbh)

Duration: 42 months, starting October 2024 (a later start date may also be considered)

Funding: Tuition fees and stipend for UK or international students

A fully-funded PhD studentship at Imperial College London, in the Department of Materials, is available from 1st October (a later start date may also be considered). The position (and full funding of tuition fees and stipend) is available to both UK and international students.

Elastomers (e.g., natural rubber) are a very versatile class of polymeric material. Their diversity of technological application is made possible by the ability to tune their constituent building blocks at multiple length-scales, from the chemical groups within individual monomers, to the molecular architecture of each polymer chain, to their overall morphology on the mesoscale and by additions such as inorganic nanoparticles to make elastomer nanocomposites.

In this project you will use theory and computer simulations to understand and predict the mechanical failure of silica-polymer nanocomposites and the mechanisms by which the chemistry of the interface influences mechanical properties. The problem is inherently multi-scale: the bond-breaking processes at the nanoparticle-polymer interface that initiate failure are quantum-mechanical in nature, yet the mechanisms by which stresses are transferred through the disordered polymer occur on length-scales far in excess of anything that can be simulated quantum-mechanically.

Building on earlier work at Imperial [1, 2], we will develop and use a hybrid, multi-scale approach in which the majority of the system is described with a computationally efficient interatomic force-field, and regions in which bond-breaking is about to occur are identified on the fly and are treated quantum mechanically. We will focus first on silica (SiO2) nanoparticles and polymers such as polyisoprene, which are commonly used in industry and atomic models for which have already been developed by researchers at Continental [3-5]. As the project proceeds we will consider a variety of different polymers and chemistries of attachment to the nanoparticles.

This project is a collaboration between Imperial College London and Continental, and there will be opportunities to spend some time during the course of the project working at Continental in Hannover, Germany.

Applicants should have a Master’s degree (or equivalent) in the physical sciences at the equivalent of a UK First or Upper Second Class. We strongly encourage applications from under-represented groups.

The funding (subject to successful completion of final stages of contractual arrangements), will cover tuition fees at the UK or international student rate plus a stipend of £21,237 per year.

Entry requirements and the application process are available at https://www.imperial.ac.uk/study/apply/postgraduate-doctoral/application-process/.

For technical and scientific enquiries, please contact Prof Arash Mostofi. For further information about the application process, please contact Dr Annalisa Neri. For further information about the Department, please see https://www.imperial.ac.uk/materials.

Closing date: applications will be assessed on a rolling basis, so early application is strongly advised.

References

[1] Golebiowski et al, J. Chem. Phys. 149, 224102 (2018); https://doi.org/10.1063/1.5035508

[2] Golebiowski et al, Phys. Chem. Chem. Phys. 22, 12007 (2020); https://doi.org/10.1039/D0CP01841D

[3] Meyer et al, Macromolecules 50, 6679 (2017); https://dx.doi.org/10.1021/acs.macromol.7b00947

[4] Hager et al, Macromolecules 48, 9039 (2015); https://dx.doi.org/10.1021/acs.macromol.5b01864

[5] Meyer et al, Scientific Reports 7, 11275 (2017); https://dx.doi.org/ 10.1038/s41598-017-11728-6

Understanding the type, distribution and mechanical properties of interfaces in geological systems.

Supervisors: Prof Finn Giuliani; Dr Katharina Marquart, Department of Materials; Dr Sam Krevor, Department of Earth Science and Engineering

Home Department: Department of Materials at Imperial College London (South Kensington Campus)

Funding and Deadline: To be eligible for support, applicants must be “UK Residents” as defined by the EPSRC1. The studentship is for 3.5 years starting ASAP and will provide full coverage of standard tuition fees and an annual tax-free stipend of approximately £19,668. Applicants should hold or expect to obtain a First-Class Honours or a high 2:1 degree at Master’s level (or equivalent) in Materials Engineering, another branch of engineering or a related science. Funding is through the project InFUSE (Interface with the future: underpinning science to support the energy transition), funded by the EPSRC and Shell.

Project summary: Carbon capture and storage (CCS) provides a very promising solution to sequester current CO2 production and allow critical process that are difficult to decarbonise to continue running into the future. Understanding the suitability of different rock types for CCS requires a detailed knowledge of among other things their mechanical properties both before and after CO2 injection. The mechanical properties of brittle materials are governed by their ability to dissipate energy which is often controlled by the properties of their interfaces. For example, weak interfaces can promote crack deflection and crack bridging mechanisms giving increased performance. These mechanisms have been studied and optimised in many structural ceramic systems however, in geological materials less work has been carried out.

In this project we propose to both measure the distribution of interfaces and interface categories within different rock types and measure the mechanical the properties of individual key interfaces. In this project you will develop skills in micromechanics, high resolution electron microscopy included EBSD and synchrotron techniques at the Diamond Light Source, the UKs national synchrotron facility. This is a key partner in the project and will support the design of novel environments to study samples under operando conditions. This would give unique insight into the microstructure of candidate rock types. This could then potentially be extended to include samples that have been exposed to supercritical CO2. This could be particularly important in basalt rocks with their ability to mineralize CO2. This allows to cracks to fill with newly formed carbonates and silicates on relatively short timescales (~1-2 years). Yet the whole process of reaction driven cracking is not well understood. This is either regarded as beneficial for safety, by preventing leakage, or as detrimental as mineralization may seal fluid paths and thus reduce permeability. It should also be noted that these research techniques are quite general and a secondary program could be applied to completely different brittle material systems, such as the build-up of damage in battery materials leading to performance degradation.

Informal enquiries about the post and the application process can be made to Prof Finn Giuliani by including a motivation letter and CV.

Validating Negative and Low Carbon Advanced Materials Innovation for Sustainable Automotive Applications

Supervisor: Prof. Julian Jones

Co-Supervisors: Prof. Jason Hallett, Dr. Elena Dieckmann

University lead: Dr. Michel-Alexandre Cardin

Start date: January 2024 (or as agreed)

Submission deadline: 15 November 2023

Project description: To achieve the sponsor’s Net Zero targets, identify and evaluate novel sustainable low-carbon materials for automotive applications, this project will explore and evaluate the properties of new advanced materials, considering, for example, biomass-derived and bio-inspired materials, high-performance polymers, and composites, as well as glass technologies in view of a more sustainable, low carbon automotive manufacturing and recycling process.

The key questions addressed in this research project are:

What are the possible environmentally friendly processes to derive and recycle polymers rapidly from biomass and bio-inspired materials?

What are the relevant mechanical properties, costs, and stability under different UV and temperature changes of the relevant processes and extracts?

The selected candidate will help us develop advanced low-carbon materials, recycling processes, and carbon capture and removal technologies of the future to support ongoing electrification and decarbonization in the automotive industry.

Please note this project is a cross-departmental initiative on sustainability at Imperial College London, Faculty of Engineering. We welcome applications from candidates with a passion for circular economy, advanced low-carbon materials, decarbonisation technologies, sustainable chemical processes and recycling, and systems thinking for the future automotive industry.

Two complimentary projects are also available in the Departments of Chemical Engineering and Design Engineering.

Funding: The PhD positions are fully funded by the EPSRC iCASE scheme and sponsored by a major British luxury car manufacturer.

Each studentship provides both stipends and cover home tuition fees for four years.

Placement opportunity: The scheme includes a minimum 3-month placement at the industrial sponsor and joint supervision with Imperial College London.

Ideal candidates: will have a passion for the environment, a vision for the future of the automotive industry, a driving ambition to explore the intersection between design, materials, and chemical engineering, and have outstanding records of academic achievements.

Applications are welcome from candidates with a background in Chemical Engineering, Design Engineering, Materials Engineering, Mechanical Engineering, Systems Engineering and/or equivalent.

To apply, email the following information to the project university lead Dr. Michel-Alexandre Cardin and supervisors as listed above.

Cover letter (1 page): please explain why you are interested in the project (specify project), what skills and expertise make you a highly competitive candidate, why you want to pursue a PhD, and a short proposal on how you would tackle the above challenges

Resume (2 pages): include all grades for your undergraduate and graduate studies (if any), evidence of impact (e.g., awards, competitive funding, publications). Note that only applicants from top universities in a relevant engineering, design, or scientific discipline will be considered, with a minimum of 2:1 or First Class (or equivalent GPA for other applicants).

Once the supervisor has agreed to support your application, please submit your application via the Application Portal. Please make sure to specify the supervisor and department associated to the project.