Chemistry Cleanroom

Since 2019 the Department of Chemistry features a class ISO7 Cleanroom (less than ten thousand particles per cubic foot of air with particle size of 0.5μm to 5μm) located at the Molecular Sciences Research Hub in White City. The 150 m2 facility contains three rooms: two for the fabrication and characterisation of devices including perovskite and organic solar cells and one dedicated to the fabrication of microfluidic devices for lab-on-a-chip and in vitro biological studies. In light of its sustainability and energy-efficient working policy, the cleanroom was recently awarded a gold award for the Lab Efficiency Assessment Framework (LEAF).

Centre for Plastic Electronics MSRH device fabrication and characterisation facility

The two rooms are predominantly used for fabrication of organic semiconducting devices (wet lab) and their optoeletronic characterisations (dry lab). The facility presents an additional dedicated area for perovskite technologies, comprising of N2 filled glovebox with balance and spin coater incorporated.

Equipment within the lab

- Chemical workstations (Class ISO5) compatible with all types of wet chemistry

- Programmable spin coaters located in both fumehoods and gloveboxes

- Hotplates located in both fumehoods and gloveboxes

- Diener Femto oxygen plasma chamber

- ZAA 2300 Zehntner-Automatic film applicator coater and R-K Knife bar coaters

- MBraun Evaporator – located in an MBraun Glovebox

- Kurt J Lesker evaporator – located in an Mbraun Glovebox

- PVE300 Bentham Photovoltaic EQE measurement system

- Lot-Oriel and Newport Solar simulators

- Alpha Step Tencor D500 Surface Profilometer

- Probe station for transistor characterisation

- Separate MBraun Glovebox complete with spincoater for Perovskite fabrication

- Four point probe, Ossilla

- Contact Angle Goniometer, Ossilla

- DRP-STAT-I400S μStat-i 400s Potentiostat/Galvanostat/Impedance Analyzer, Metrohm

Cleanroom

Cleanroom dry lab with glovebox facilities for handling air sensitive organic materials and evaporations of different types of electrode materials

Cleanroom dry lab with Perovskite device fabrication glovebox

Cleanroom wet lab facilities for handling all wet chemistry for fabrications of devices such as OLED, diode, solar cells and transistor fabrications

Microfabrication lab

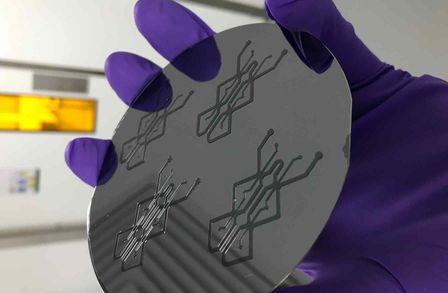

The Microfabrication lab is a dedicated area for rapid prototyping of Polydimethylsiloxane (PDMS) microfluidic devices by soft lithography, with lab-on-a-chip and organ-on-a-chip applications. Photolithographic patterning of silicon wafers is conducted in an ISO Class 5 cleanroom environment inside chemical workstations.

Equipment within the microfab lab

- Chemical workstations (Class ISO5) compatible for wet chemistry required for the microchip fabrication

- Laminar flow bench for dry substrate treatments

- Optical lithography (Photolithography)

- Programmable spin coater

- Programmable hotplates

- Rapid prototyping of PDMS microdevices

- Collimated UV light source

- Diener Zepto plasma system

- Wet etching facilities

- Optical microscope

Microfabrication lab

Microfabrication Wet lab. Credit: Alex Ainscough; Joshua Edel

Pulmonary artery-on-a-chip, example of PDMS organ-on-a-chip devices. Credit: Alex Ainscough; Joshua Edel

SU-8 Photolithographic patterning on silicon wafers. Credit: Manfredi San Germano; Oscar Ces

Registration and enquiries

These facilities are available to members of college, and we also encourage enquiries from outside the college, including academic, commercial and industrial users. To register as a Cleanroom user and for all other enquiries please contact:

Dr. Pabitra Shakya Tuladhar (Cleanroom Manager)

e-mail: p.shakya@imperial.ac.uk

Tel: +44 (0) 207 594 5710