Examples of our collaborations

Faculty of Medicine has worked with a wide variety of industries and organisations, below are short case studies of our collaboration:

Examples of our collaborations

Shell

A multidisciplinary approach to tackle corrosion

The Shell-Imperial Advanced Interfacial Materials Science (AIMS) Centre was launched in March 2016 with the aim of delivering new insights into materials behaviour and enabling optimal materials selection, design and enhanced predicative capabilities.

The Centre, based in the Department of Materials, focuses on the development of innovative solutions using state-of-the-art and in operando characterisation approaches to materials challenges in the engineering and energy industry.

The Centre focuses on five technical themes exploring research that links nanoscale processes to large-scale materials behaviour.

The interdisciplinary research team, which includes six PhD students and three Post-Docs, has been exploiting developments in new ambient pressure systems for spectroscopy and microscopy, as well as central synchrotron facilities to develop new in-situ approaches to study complex systems over length and timescales relevant to industrial processes. The long-term goal of the Centre is to make industrial processes safer, more predictable and more efficient, ultimately resulting in better asset management and operational performance.

Jaguar Land Rover

Renewed commitment to engine research

Jaguar Land Rover has resumed the Centre of Excellence for Spark-Ignition Engine Combustion Research at Imperial for a period of five years.

The Centre was originally established at University College London in 2013, led by Professor Pavlos Aleiferis. In 2016, however, Professor Aleiferis was appointed as Chair in Thermofluids in Imperial’s Department of Mechanical Engineering, prompting its movement.

Professor Aleiferis' research expertise in the fundamentals of fuel systems and internal combustion engines for low-carbon vehicles has been historically utilised by a number of automotive companies including Honda, where he originally completed postdoctoral research into optical techniques applied to internal combustion engines.

The JLR Research Centre will continue to form an integral component of the company’s commitment to producing fuel-efficient powertrain technologies and the findings will help considerably to deliver the company’s ambitious goal of a 25% reduction in CO2 emissions by 2020 to comply with both governmental policy and broader consumer demand.

The Imperial team will focus on Thermodynamic Single Cylinder and Optical Single Cylinder Engines with student research projects in Experimental Combustion and Computational Fluid Dynamics (CFD) Research and Development running in parallel up until 2021.

Thomson Reuters

Big data challenges in finance and law

The Data Science Institute, Imperial College London and Thomson Reuters are working together to bring data science expertise from both corporate and academic worlds to bear on global big data challenges impacting financial and legal professionals. The initiative aims to drive faster innovation in FinTech and RegTech industries through collaborative research projects.

The Data Science Institute, Imperial College London and Thomson Reuters are working together to bring data science expertise from both corporate and academic worlds to bear on global big data challenges impacting financial and legal professionals. The initiative aims to drive faster innovation in FinTech and RegTech industries through collaborative research projects.

The projects bring together academics from across Imperial to do cutting edge research informed by real industry problems. The collaboration will utilise the KPMG Data Observatory to visualise data, enabling novel exploration of data and unearthing fresh insights.

This partnership will create a global ecosystem whereby academics, financial markets institutions, and technology firms can collaborate to tackle FinTech issues such as supply chain risk, financial risk management, real-time data analysis and RegTech issues such as the impact of regulation.

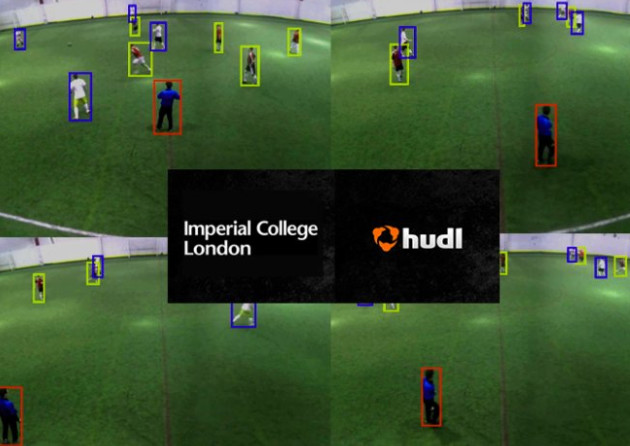

Hudl

Improving sports tracking software

Imperial has been working with the rapidly expanding US software company Hudl to improve its sports tracking technology.

Imperial has been working with the rapidly expanding US software company Hudl to improve its sports tracking technology.

The software, which is used by thousands of professional and amateur sports teams globally, uses video recording to track the movement of players at games or training sessions, enabling coaches to document vital statistics. Coaches can then interactively annotate the footage and forward it to players to use to perfect their performance or create a showcase of their skills.

To help improve the accuracy of these products researchers in the Department of Electrical and Electronic Engineering have been working with the company to develop new algorithms and computer software, and overcome technical challenges such as gaps between observations, dynamic appearance changes of players (e.g. due to different viewpoints and light conditions) and limited resolution of images.

The project was completed by the Computer Vision and Learning Lab, led by researcher Dr Rigas Kouskouridas and the laboratory's head, Dr Tae-Kyun Kim.

Dyson

Developing next generation robots

Since 2014 The Dyson Robotics Lab at Imperial College has developed computer vision programmes that enable robots to move beyond traditionally controlled environments and successfully navigate the real world.

Since 2014 The Dyson Robotics Lab at Imperial College has developed computer vision programmes that enable robots to move beyond traditionally controlled environments and successfully navigate the real world.

Developing robots that can process visual information in real-time could lead to a new range of handy and helpful robots for around the home and in industry.

The collaboration, which fits with Dyson's plans to develop new robotic technology, comes at a time when other major technology companies such as Google, Amazon and Microsoft are buying up artificial intelligence and robotics companies in an effort to move toward the next generation of intelligent computing for the home and work.

Together with Dyson, Imperial continues to push the state-of-the-art forward.

ABB

Tomorrow's technology for today's students

In 2012, following investment from ABB and a long term maintenance commitment, the Department of Chemical Engineering opened a £2million carbon capture pilot plant, believed to be one of the most sophisticated facilities of its kind in the world.

In 2012, following investment from ABB and a long term maintenance commitment, the Department of Chemical Engineering opened a £2million carbon capture pilot plant, believed to be one of the most sophisticated facilities of its kind in the world.

The pilot plant gives undergraduates the chance to learn key operational skills. As a result, students graduate from Imperial with an unrivalled expertise, making them more employable in an increasingly competitive sector.

For ABB, this is an investment which ensures that the company will have ready access to a stream of suitably qualified engineers, who are well aware of the benefits of a career in control and instrumentation engineering when they graduate.

In addition, ABB has access to the plant and control room for its own use and uses the facility for customer demonstrations and training, staff learning, and hands on experience for its apprentices and graduate engineers, as well as for product testing.

Shell and Qatar petroleum

A collaborative approach

The Qatar Carbonates and Carbon Storage Research Centre (QCCSRC) was set up to investigate some of the most important challenges in the exploitation of carbonate reservoirs; cleaner methods for the production and use of oil and gas, as well as more efficient recovery, for example.

The Qatar Carbonates and Carbon Storage Research Centre (QCCSRC) was set up to investigate some of the most important challenges in the exploitation of carbonate reservoirs; cleaner methods for the production and use of oil and gas, as well as more efficient recovery, for example.

Research in these areas is crucial to the reduction of the release of carbon dioxide into the atmosphere and to the mitigation of climate change.

As part of the QCCSRC programme, academics are exploring how to store carbon dioxide deep underground in layers of permeable rock.

To do this, multi-scale x-ray CT technology - more commonly used in hospitals to visualise internal structures of the body - is being used to look at carbonate rock formations on the microscopic scale, in order to better understand the way carbon dioxide interacts with, and flows within, these materials.

Eli Lilly

Eli Lilly has committed £5 million to fund research into the more efficient manufacture of medicines, which could ultimately result in better and cheaper treatments for patients.

The money is being used to fund a virtual lab, led by Imperial and supported by UCL, to apply Process Systems Engineering (PSE) methods to the pharmaceutical industry. PSE uses computer assisted methods and models to design, control and optimise processes. The approach has previously been used in the petrochemical, chemicals, and consumer goods industries.

The Pharmaceutical Systems Engineering Lab (PharmaSEL) falls under the remit of Imperial and UCL's Centre for Process Systems Engineering (CPSE).

New methods

Applying PSE methods to the pharmaceutical industry has the potential to increase efficiency, decrease wastage and resolve quality control issues across the manufacturing process. PharmaSEL will seek to catalyse the creation of such methods and will accelerate their adoption in the industry.

Over an initial period of six years, researchers are focusing on three main themes: building more predictive models; designing more effective experiments; and improving the design of pharmaceutical manufacturing systems.

The first phase of work focuses on developing virtual models that better anticipate the outcomes of physical experiments. By improving foresight in the modelling of basic pharmaceutical compounds, researchers will be able to reduce the time to market, as well as the wuality and effectiveness of drugs.

Multidisciplinary collaboration

The new lab's work builds on a project funded by Lilly in 2015 and led by Professor Claire Adjiman, Director of CPSE and Imperial's Institute for Molecular Sciences and Engineering (IMSE).

This early research used computer-aided design to prove that the ability to predict solubility of molecules is directly relevant to successful drug development, setting the groundwork for future investigations.

Professor Adjiman said: "The application of research to practice is core to CPSE's ethos. This collaboration is an exciting opportunity to translate fundamental research breakthroughs into methods that can be used time and time again by the pharmaceutical industry to develop improved medicines and manufacturing processes."

HeartFlow

HeartFlow collaboration brings personalised heart disease diagnosis closer

Imperial's bioimaging experts are partnering with the Californian SME HeartFlow to improve how the company models the heart's blockages.

HeartFlow offers a non-invasive method to detect and quantify blockages in arteries by using 3D scans of patients' hearts to simulate blood flow and aid diagnosis.

Academics from the Department of Computing will now assist the company in developing new algorithms that 'learn' and improve as they analyse datasets to provide increasingly accurate models.

The collaboration will be led by Imperial's Dr Ben Glocker and Professor Daniel Reuckert and will involve co-locating a HeartFlow team at the College.

Dr Glocker, Senior Lecturer in Medical Image Computing said "The collaboration with HeartFlow will not only open new and exciting research directions, but it will also pave the way for bringing our latest deep learning technology into clinical practices and thus will have real impact on the healthcare of thousands of patients."

HeartFlow will also fund additional research roles at the lab. The team will work on a joint project initially focused on developing algorithms for extracting models of the coronary arteries from 3D scans over time, improving alignment of images and improving the precision of image acquisition and reconstruction.

Mitsubishi Heavy Industries

Imperial College London have been partnering with Mitsubishi Heavy Industries (MHI) since 2005 to improve turbocharger design

Imperial College London have been partnering with Mitsubishi Heavy Industries (MHI) since 2005 to improve turbocharger design

Long-term partnership with a world-leading manufacturer

Mitsubishi Heavy Industries Ltd (MHI) is a key collaborator with Imperial and has invested in a major partnership that began in 2005. The collaboration has had a significant impact on MHI, with substantial improvements in turbocharger design as a result of more advanced measurement techniques and simulation tools.

MHI makes industrial machinery and equipment, including the manufacture of gas turbines, turbochargers and internal combustion engines. It is a global leader in R&D investment, spending £1bn in FY2016, enabling it to enhance its competitiveness, particularly in the energy and environment sectors.

The Imperial-MHI partnership has to date mainly focused on improving technologies in enhanced turbochargers, and enhancing ways for evaluating them. It is led by Professor Ricardo Martinez-Botas, who heads up the Turbocharger Group and the Thermofluids Division in Imperial’s Department of Mechanical Engineering.

Fruitful relationship

Imperial’s partnership with MHI has harnessed the expertise of Professor Martinez-Botas and his research group, enabling them to apply their knowledge and tools to solve a range of industry-led problems. The most significant recent impact has come from a new turbine, which has improved performance under pulsation and led to improvements in engine level fuel economy. The conventional radial turbine has been replaced with a modified turbine blade in a new volute that brings out the system’s potential under a pulsating condition. A joint patent on the volute was filed in 2013 and series production began in 2016. In the same year it received MHI’s Best Innovation Award.

The successful Imperial-MHI partnership has subsequently led to other concepts for MHI, including a new turbine nozzle and compressor volute. More recently, a new testing procedure has been jointly implemented in the Turbocharge Technology Laboratory at Imperial, which could make significant improvements in our current understanding. Other outputs include joint publications and PhD training.

Broader impact

In 2017, the new partnership expanded to cover work with the Combustion and Tribology Research groups. For example, work with Professors Alex Taylor and Yannis Hardalupas has led to a research programme for combusting two phase flows. A collaboration with Dr Amir Kadiric is working on an analytical model for understanding of contact behaviour in relation to efficiency and reliability improvement in mechanical components.

At the same time, a collaboration between MHI and the Centre for Low Carbon Transport in cooperation with Imperial College London at the University of Technology, Malaysia (UTM) has been launched to translate concepts from the Imperial-MHI partnership to realistic engine conditions.

Future collaboration

In addition to the impacts described above, the Imperial-MHI partnership has generated a healthy pipeline of future collaboration opportunities. These include technology for further improvement of the turbocharger and turbocharging system for future powertrains.

Kaesler Nutrition

In 2018 researchers in Imperial’s Department of Bioengineering joined forces with German animal feeds producer Kaesler Nutrition to kick-start the company’s in-house production of carotenoids.

In 2018 researchers in Imperial’s Department of Bioengineering joined forces with German animal feeds producer Kaesler Nutrition to kick-start the company’s in-house production of carotenoids.

Carotenoids are naturally-occurring, fat-soluble additives that Kaesler and other feed producers add to their products to improve appearance and nutritional quality. Previously Kaesler bought in and refined these essential additives from other natural sources but began to explore ways to produce them completely in-house. However, carotenoids can be difficult to synthesise, with the traditional process producing relatively low yields with high production costs.

In research circles, a microbial-centred approach has shown early success in improving yields. Led by synthetic bioengineer Dr Rodrigo Ledesma-Amaro, a team of Imperial bioengineers are pioneering a yeast-based approach to apply to Kaesler’s synthesis process, which will expand the company’s current production capabilities.

The 2-year project was part of a wider programme of academic engagement for Kaesler, who also sponsored complementary research projects with two German universities.

“This collaboration is a great opportunity for us to increase the speed of execution of this project. We will do this by leveraging complementary expertise between the different working groups. We are excited to work with Imperial’s researchers to translate their unique expertise in microorganism engineering into industrially relevant processes,” said Dr. Heiko Dietz, Head of R&D at Kaesler Nutrition.

Research staff are based between England and Germany to ensure the teams can work unhindered. An exchange of students and materials will further support knowledge transfer in the partnership.

“Collaborating with relevant industry partners, such as Kaesler, is a very rewarding experience,” Dr Ledesma-Amaro commented. “It allows us to close the gap between cutting edge academic achievements and an impact in the real world. We are thus very excited to begin this collaboration with Kaesler Nutrition, which could lead to innovative biotechnological and bioengineering processes.”

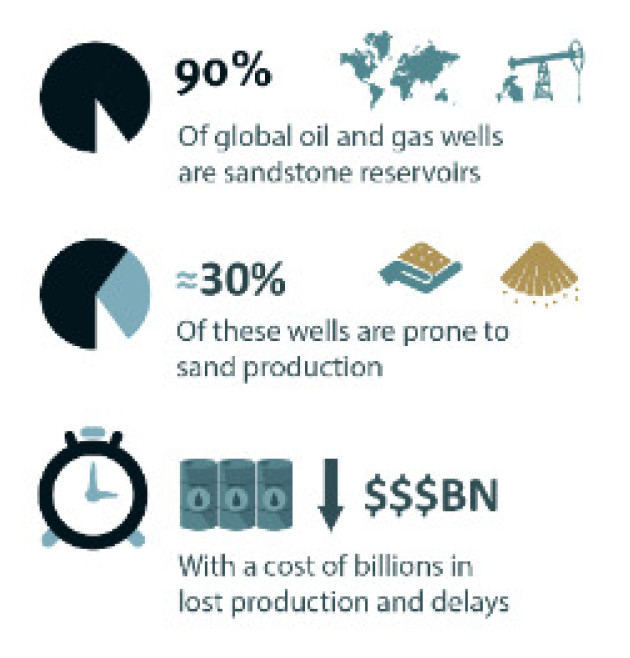

Petronas

PETRONAS partner with Matar Fluids Group to control sand in wells

PETRONAS partner with Matar Fluids Group to control sand in wells

It is estimated that 90% of oil and gas wells drilled around the globe are in sandstone reservoirs, with approx. 30% of them being prone to sand production. With reservoir pressure depletion and water breakthrough, sand production is expected to worsen over time in these wells, making sand control or sand management an inevitable challenge throughout a well's lifetime.

The challenges associated with excessive sand production in sandstone reservoirs have been estimated to cause billions of dollars of losses to the oil and gas industry each year. Issues include equipment and fitting damage caused by erosion, production deferment and HSE concerns - the latter due to excessive sand disposal and handling requirement on the production platform.

One commonly used sand control method is chemical injection into a sand-prone well as a preventative or remedial measure. In this instance, resin-based chemical formulation is typically employed, however, this approach may have a negative impact on hydrocarbon production. Re-treatment of wells is also necessary as the chemicals deteriorate over time.

The PETRONAS-Imperial team is developing a novel formulation for chemical sand control to overcome limitations associated with the industry's conventional chemicals solutions. The novel formulation for sand control aims to agglomerate sand particles without affecting hydrocarbon production. Additionally, the novel chemical is thermally and chemically robust enough for re-treatment to be required less frequently.

The key enablers for this chemical development are the state-of-the-art experimental facilities for detailed understanding of the sand agglomeration process, for example, real-time particle tracking probes and the customizable core-flooding test rig.

The team has also developed a reliable agglomerate growth prediction model. Computational modelling has been a crucial element in bridging understanding from laboratory to actual field conditions, proving to be a platform for accelerated technology development.

Moving forward, PETRONAS is looking to move to a pilot application of this technology in several fields in 2018.